Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

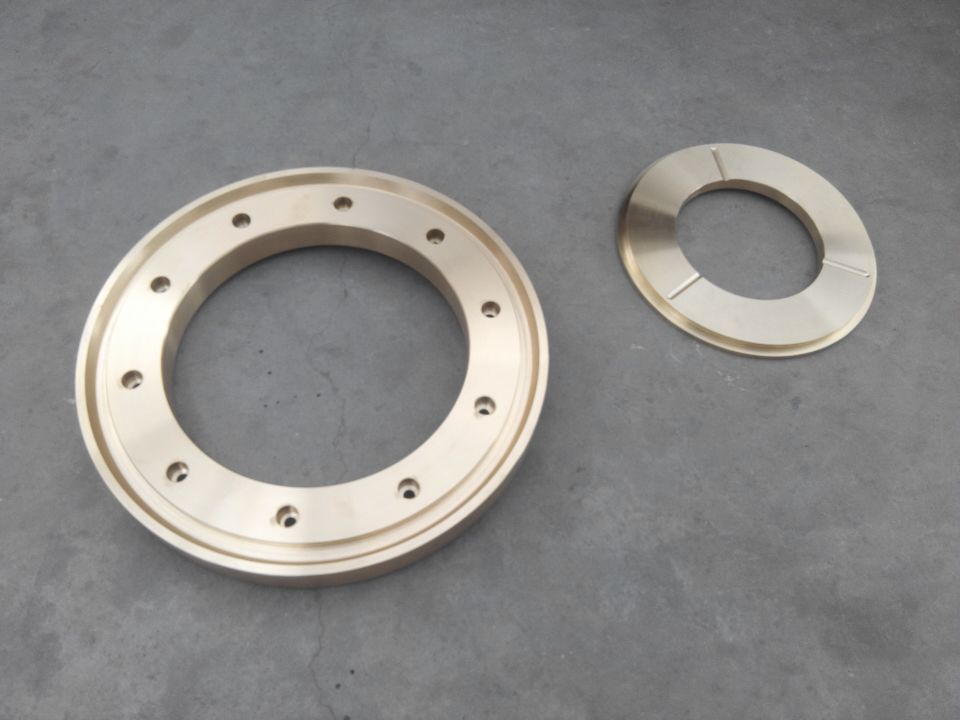

Cell phone +86 17630258963 Plumbing: Used to create leak-proof seals in pipes and fittings.

Automotive: Utilized in engines, transmissions, and other components requiring reliable sealing.

Electrical Systems: Employed in electrical connections to ensure conductivity and grounding.

Machinery: Used in various mechanical assemblies to provide a tight seal and prevent leaks.

Automotive Industry: Used in engines, exhaust systems, and other high-temperature components.

Aerospace: Suitable for aircraft engines and other systems exposed to extreme temperatures and pressures.

Industrial Machinery: Employed in pumps, compressors, and hydraulic systems where high temperatures and pressures are common.

Power Generation: Used in turbines and generators for their heat dissipation and conductivity properties.

Chemical Processing: Ideal for sealing in harsh chemical environments due to their corrosion resistance.

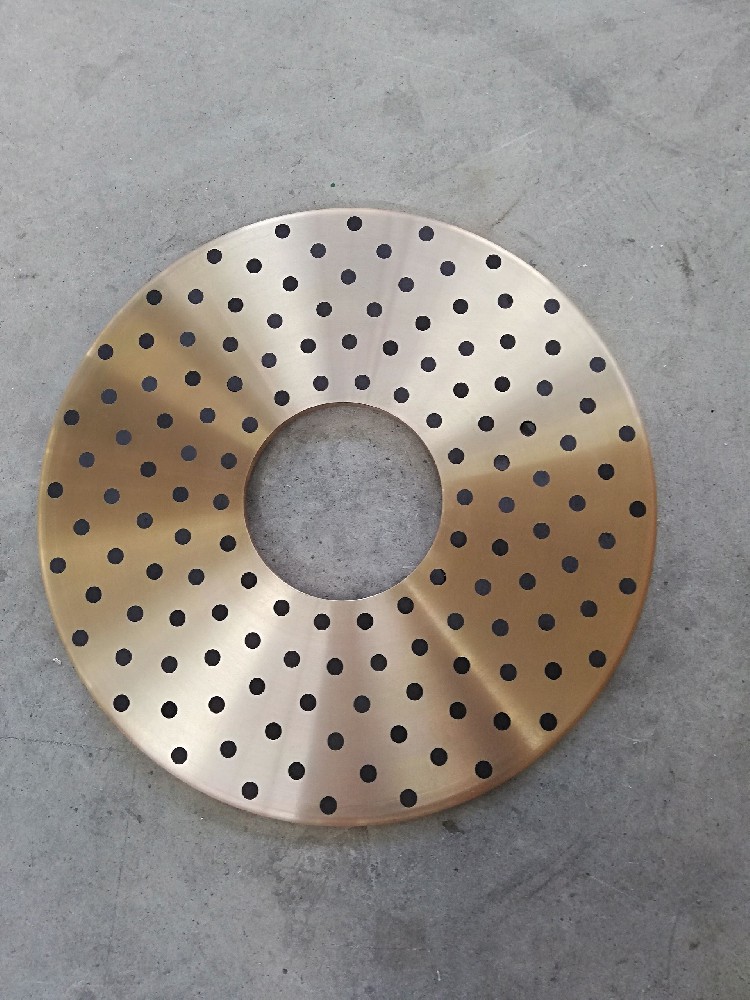

Lubrication: Graphite copper gaskets provide self-lubrication, reducing the need for external lubrication and decreasing wear.

Heat Resistance: Graphite copper gaskets are better suited for high-temperature applications than pure copper washers.

Sealing and Flexibility: Graphite copper gaskets are more flexible and conform better to surface irregularities, providing a more reliable seal in some applications.

Corrosion Resistance: While both types offer good corrosion resistance, graphite copper gaskets have an edge due to the combined properties of copper and graphite.

Choosing between copper washers and graphite copper gaskets depends on the specific requirements of the application. Copper washers are excellent for general sealing, electrical, and thermal applications, while graphite copper gaskets are preferred for high-temperature, high-pressure environments, and applications where self-lubrication and enhanced sealing capabilities are crucial.