Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 In many fields such as mechanical manufacturing, copper sleeves and steel sleeves are common components. So which material is more wear-resistant?

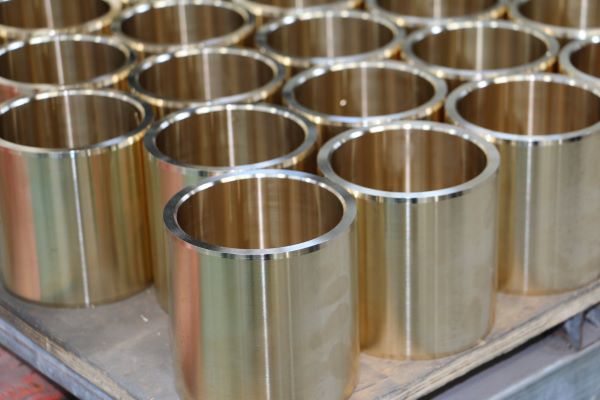

Copper sleeves have their own unique advantages. Copper itself has a relatively soft texture, but it has good self-lubricating properties. In some operating environments with relatively low speeds, light loads, and low requirements for friction coefficient, copper sleeves can reduce friction losses with contact parts due to their self-lubricating characteristics, thereby exhibiting good wear resistance to a certain extent. Moreover, copper has good corrosion resistance, which can cope with working conditions with slight corrosive media and extend its service life.Steel sleeves usually have high hardness, especially alloy steel sleeves that have undergone special heat treatment, which have high strength and good wear resistance. Under high-speed and heavy-duty working conditions, steel sleeves can rely on their own high-strength hard anti friction properties to maintain good dimensional stability and are less prone to excessive wear and deformation.

It's actually difficult to say which one is more wear-resistant, copper sleeve or steel sleeve, depending on various factors such as the specific usage environment, load size, speed, and the presence of corrosion. Only by making reasonable choices based on actual working conditions can they each exert their best wear resistance performance.