Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

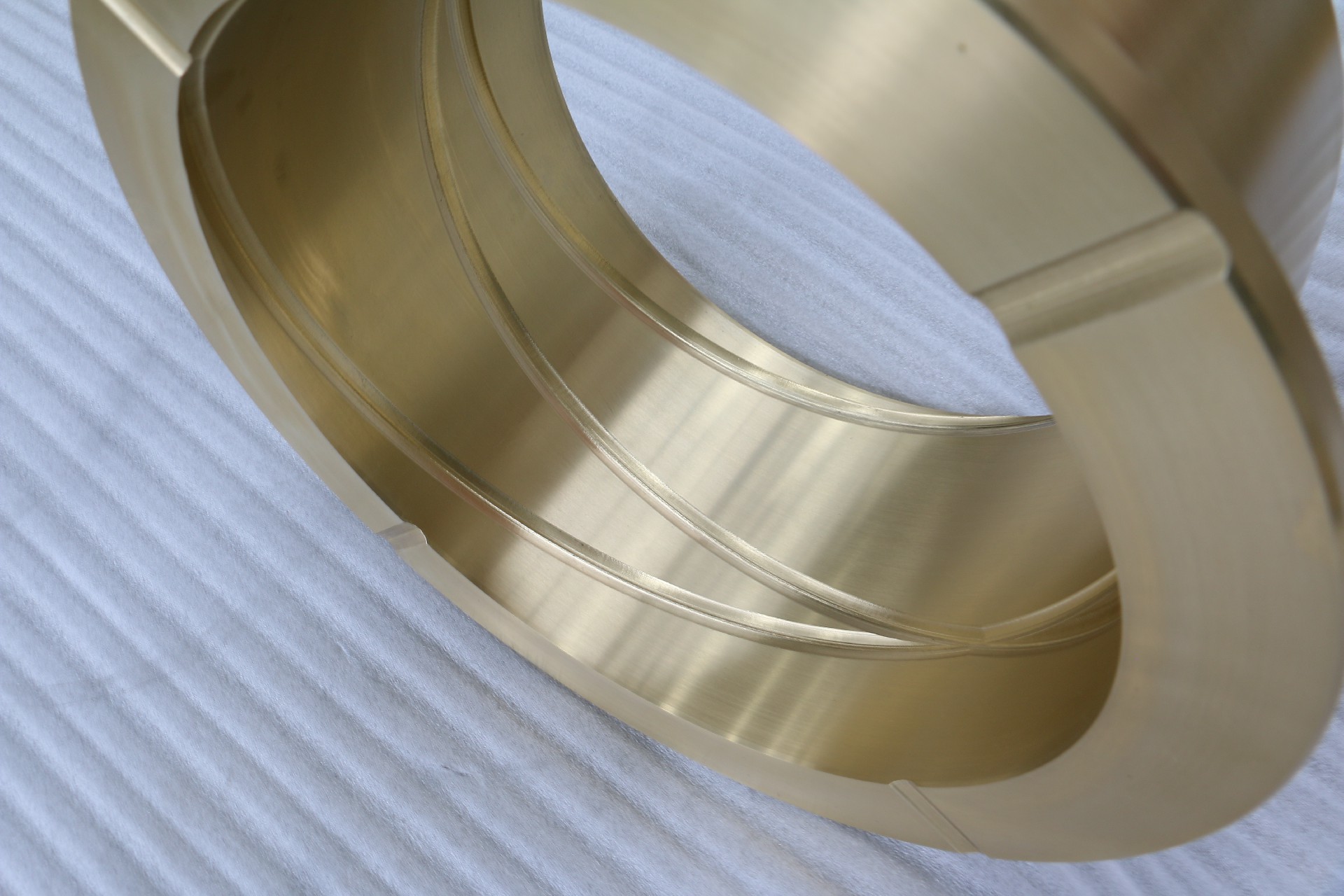

Cell phone +86 17630258963 Increasing the lubricity of bronze bushings can be achieved through a variety of methods to reduce friction and wear and improve the performance and life of mechanical parts.

1. Use self-lubricating materials:

Graphite inserts: embed graphite blocks or graphite particles in the bronze bushing to reduce friction by using the self-lubricating properties of graphite.

Solid lubricants: add solid lubricants such as molybdenum disulfide and polytetrafluoroethylene (PTFE) to the surface or inside of the bronze bushings to enhance the lubrication effect.

2. Design improvement:

Oil groove design: design spiral grooves, linear grooves and other oil grooves on the inner surface of the bronze bushing to store and transport lubricating oil so that the lubricating oil is evenly distributed on the friction surface.

Optimize geometry: optimize the geometry of the bronze bushing, such as adding lubrication holes, optimizing the fit clearance, and improving the distribution and flow of lubricating oil.

3. Lubrication system:

Automatic lubrication system: use automatic lubrication systems, such as oil pumps, oil cups, etc., to regularly provide lubricating oil to the bronze bushing to maintain a stable lubrication effect.

Lubricant selection: Select the appropriate lubricant, and select the lubricant with appropriate viscosity, oxidation resistance and anti-wear performance according to the working conditions.

4. Add lubricant:

Grease: Use grease to fill the oil groove or lubrication hole. Grease is more stable than lubricating oil under high temperature and heavy load conditions.