Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

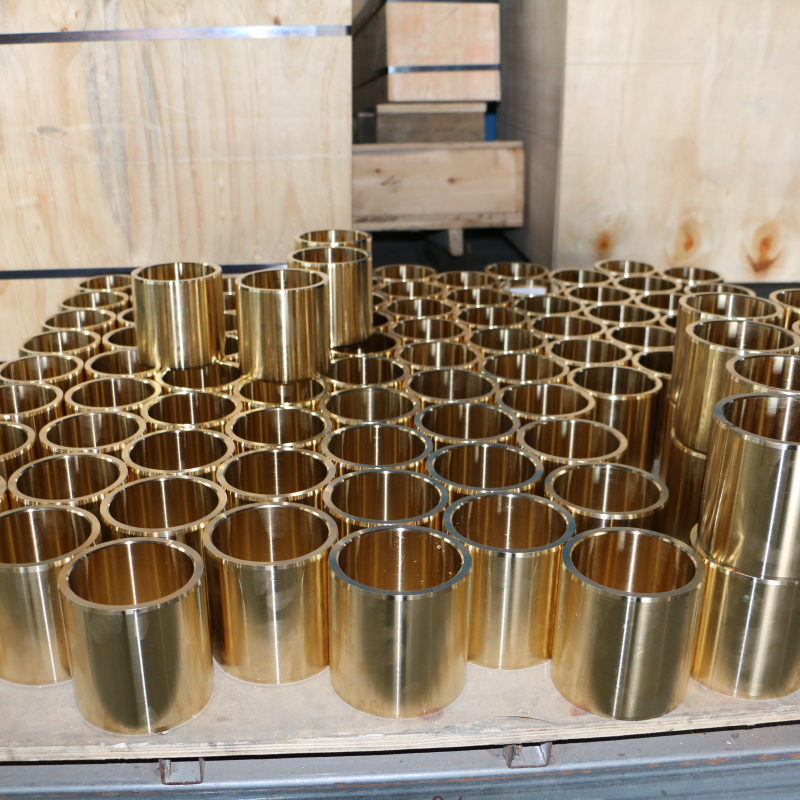

Cell phone +86 17630258963 Difference between brass bushings and bronze bushings application scenarios:

Commonly used in general mechanical parts, plumbing fittings, valves and so on. Because of its relatively low cost and good processing performance, it is widely used in some occasions that do not require high performance.

For example, in some small motors, pump equipment, brass bushings can be used as bearings or shaft tiles.

Tin bronze bushings: are widely used in bearings, bushings, worm gears and other parts in the fields of shipbuilding, chemical industry, machinery and so on. Tin bronze bushings excel in occasions that require high wear resistance and corrosion resistance, such as ship propeller shaft tile, chemical pump bearings and so on.

Aluminum bronze bushings: mainly used in high-strength, corrosion-resistant occasions, such as mining machinery, metallurgical equipment, marine engineering and so on. For example, in the shaft tile of mining crusher, the spreader of offshore drilling platform and other parts, aluminum bronze bushing can withstand great pressure and impact, and at the same time has good corrosion resistance.

Beryllium bronze bushings: commonly used in precision instruments, electronic appliances, aerospace and other fields. Because of its high elasticity, high strength and good conductivity, it can be used as spring, electrode, contact and other parts. Beryllium bronze bushing is the ideal choice in some occasions that require very high dimensional accuracy and performance.