Bronze bushing: Bronze bushing (also called bronze bushings, bronze bearings, bronze bushings) is a very critical part of the mechanical equipment in the copper fittings. His role is:

1、reduce the equipment in the operation of the sliding friction, reduce power loss.

2、Greatly increase the service life of wear-resistant parts in the running equipment, reduce repair and maintenance costs, and strive for higher utilization rate of the equipment.

3、effectively protect the steel parts in contact with them from wear and tear, when the copper parts are worn out and easy to replace.

The installation part of the oil groove copper sleeve is located in the transmission equipment between the spindle and the support frame, bear the pressure is very large, his material and size requirements are relatively high, especially between him and the spindle and steel bracket clearance is an important technical difficulties, due to the manufacturing and installation errors, in the operation is easy to cause the copper sleeve crack or even broken, spindle abrasion, cracking, and other malicious equipment accidents. So the choice of material and processing size to ensure that the oil groove copper sleeve is the key to normal operation of the equipment. The wear frequency of oil groove copper sleeve according to the use of working conditions and lubrication and copper sleeve material is closely related.

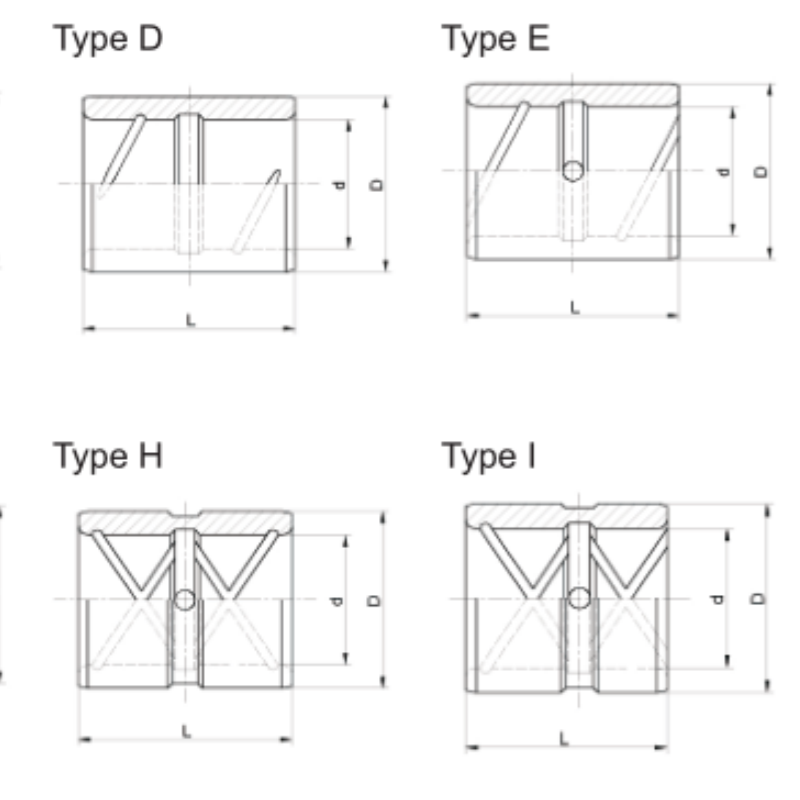

Copper sleeve oil groove processing methods

Pitch should be hung twice the length of the workpiece, the lowest speed, positive and negative threads of each car, threaded joints are fully optimized.

Oil groove copper bushing, divided into a variety of, including machine copper rollers, copper bearings and so on. Oil lubricated bearings, used in a variety of large, heavy machinery, is an important component of machinery. Copper bushings have high hardness, excellent wear resistance, not easy to produce the phenomenon of biting, good casting performance and cutting performance, good corrosion resistance in the atmosphere and fresh water.

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China