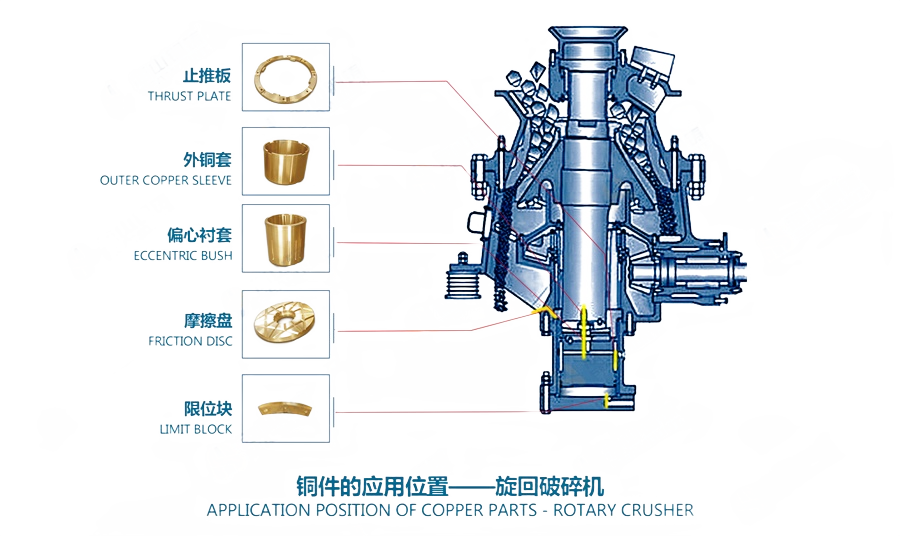

The copper sleeve of the rotary crusher includes:

Upper and lower friction discs, frame bushings, eccentric copper sleeves, thrust bearings, copper slip rings.

Upper bronze plate:

The main shaft is equipped with a bronze plate, located above the middle steel plate, which is a vulnerable part.

Lower bronze plate:

The piston is equipped with a lower bronze plate, located below the middle steel plate, which is a vulnerable part. The material is mostly made of aluminum bronze with high hardness and good mechanical properties, and is processed through a metal mold casting process.

Frame bushing:

Also known as outer copper sleeve, spindle bushing, and copper sleeve, the material is mostly high lead bronze,

eccentric bush:

Also known as eccentric sleeve, drive gear shaft copper sleeve, inner copper sleeve, etc. The material is high lead bronze,

Thrust bearing:

Also known as the thrust bearing middle plate, pressure ring, etc., its function is to reduce wear on parts, fix, and protect large mechanical components. The material is mostly made of aluminum bronze with high hardness and good mechanical properties, and is processed by centrifugal casting process.

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China