Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 In the crusher, copper bushings (copper sleeves) have many classifications, mainly classified according to their structure, materials and applications. The following are some common copper bushing classifications:

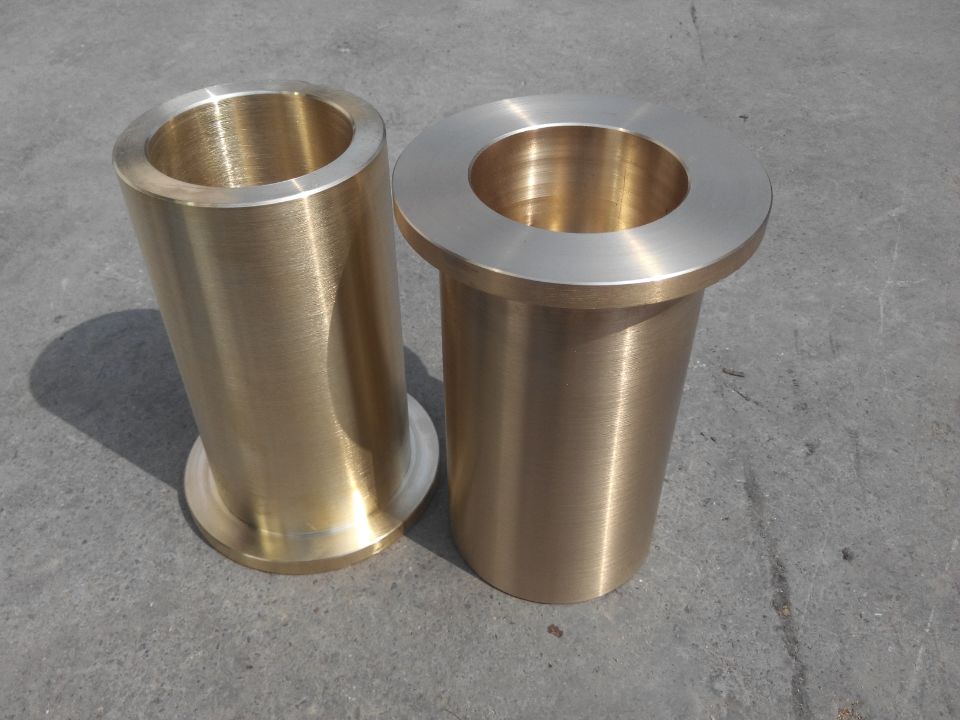

Cylindrical copper bushing: used to support the rotational movement of the shaft, with a simple structure and good load-bearing capacity.

Flange copper bushing: with flange edge, used to prevent axial movement, often used in parts that require precise positioning.

Split copper bushing: consists of two parts, easy to install and replace, suitable for large mechanical equipment.

Bronze bushing: made of copper and tin alloy, with good wear resistance and corrosion resistance, suitable for high load and high speed operation occasions.

Brass bushing: made of copper and zinc alloy, with good thermal conductivity and electrical conductivity, suitable for general mechanical applications.

Aluminum bronze bushing: made of copper and aluminum alloy, with high strength and good corrosion resistance, suitable for marine environment and high temperature applications.

Manganese bronze bushing: made of copper and manganese alloy, with extremely high strength and wear resistance, suitable for high pressure and high load applications.

Spindle copper bushing: used to support the main shaft of the crusher, requiring high wear resistance and high strength to ensure the stable operation of the main shaft.

Eccentric copper bushing: used for the eccentric part of the crusher, bearing uneven loads, requiring high wear resistance and impact resistance.

Connecting rod copper bushing: used to connect the various moving parts of the crusher, requiring wear resistance and impact resistance to ensure the smooth operation of the crusher.

These different types of copper bushings play a vital role in the crusher, ensuring the normal operation of the crusher by reducing friction, extending equipment life, and improving work efficiency.