Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

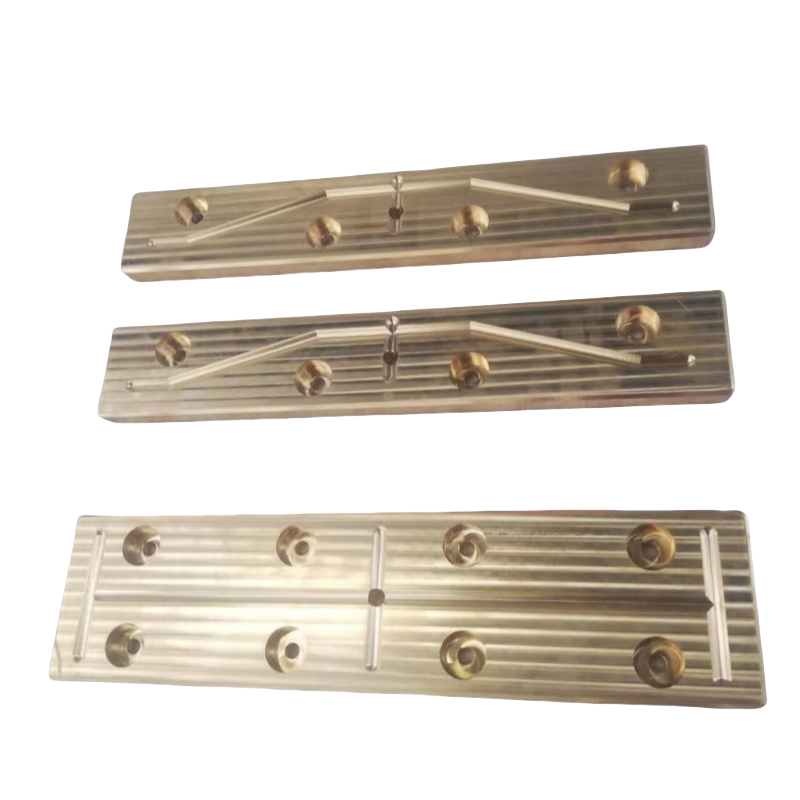

Cell phone +86 17630258963 In the crusher, the copper plate is an important wear-resistant part, which is mainly used to reduce wear, increase mechanical strength and provide lubrication function. The classification of copper plates can be divided according to their materials, structures and applications. The following are common copper plate classifications:

Bronze plate: Made of copper and tin alloy, it has good wear resistance and corrosion resistance, suitable for high load and high friction environment.

Brass plate: Made of copper and zinc alloy, it has good thermal conductivity and electrical conductivity, suitable for general mechanical applications.

Aluminum bronze plate: Made of copper and aluminum alloy, it has high strength and good corrosion resistance, suitable for marine environment and high temperature applications.

Manganese bronze plate: Made of copper and manganese alloy, it has extremely high strength and wear resistance, suitable for high pressure and high load applications.

Flat copper plate: The surface is flat, used to withstand the sliding friction between the various parts of the crusher, and provides good wear resistance.

Inlaid copper plate: Embedded with solid lubricants such as graphite, molybdenum disulfide, etc., it can provide self-lubricating function during work and reduce friction and wear.

Slotted copper plate: The surface has lubrication grooves that can store lubricating oil or grease, provide continuous lubrication and reduce wear.

Guide copper plate: Used in the guide rail part of the crusher, providing a wear-resistant layer for sliding friction to ensure smooth movement of crusher parts.

Gasket copper plate: Used to adjust the gap between mechanical parts, provide stable support and lubrication, suitable for key parts of the crusher.

Bearing copper plate: Used in the bearing seat, providing a low-friction sliding surface to reduce wear between the shaft and the bearing seat.

The application of these copper plates in the crusher can effectively improve the working efficiency of the equipment, extend its service life and reduce maintenance costs.