Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 Thrust bearings in crushers are mainly used to bear axial loads and keep the shaft positioned and stable. According to their structure and application requirements, thrust bearings in crushers can be divided into the following categories:

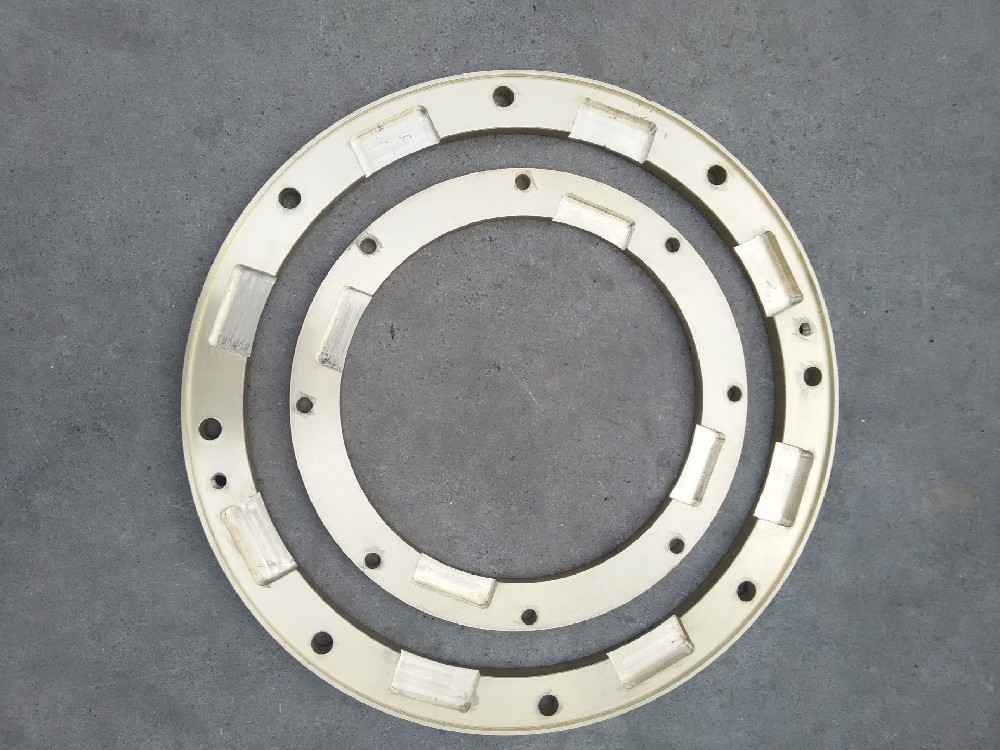

Structure: It consists of a bearing race, a thrust plate and a rolling element.

Features: It is suitable for bearing smaller axial loads and is often used in small crushers or light load applications.

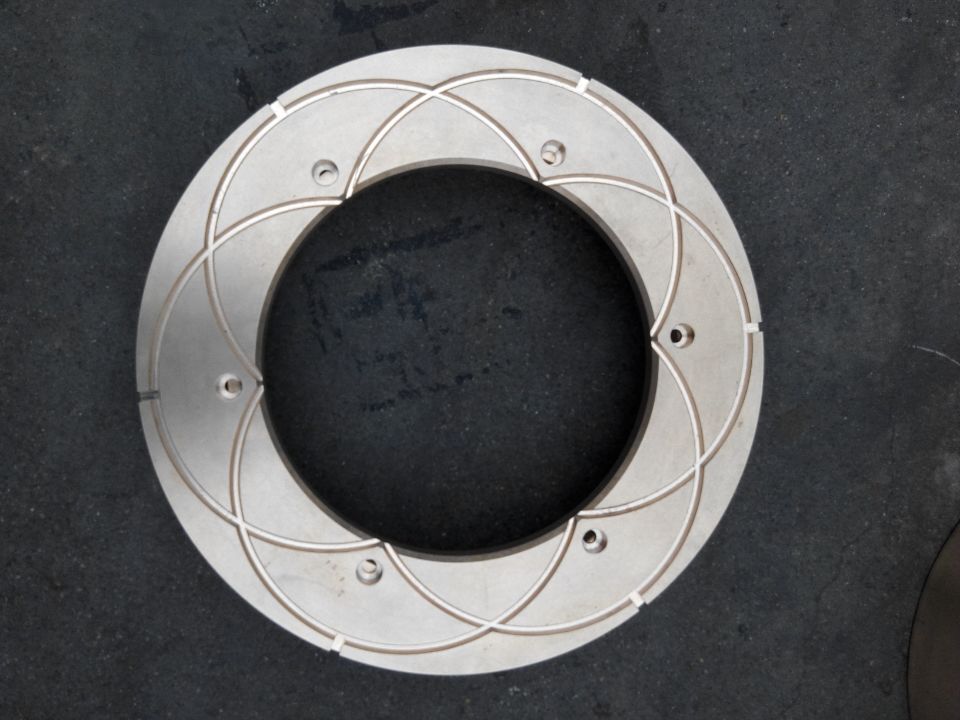

Structure: It has spherical rolling elements and allows a certain angle adjustment.

Features: It is suitable for bearing medium axial loads and certain radial loads and is widely used in medium-sized crushers.

Structure: It consists of an inner ring, an outer ring and a tapered roller, and the rollers are arranged in a tapered shape with the bearing axis.

Features: It has a high load-bearing capacity and is suitable for bearing larger axial loads and certain radial loads and is often used in heavy crushers.

Structure: It consists of an inner ring, an outer ring and a cylindrical roller.

Features: Suitable for bearing large axial loads, with high rigidity and stability, often used in large crushers or heavy-load applications.

Structure: It is composed of two thrust bearings and can bear bidirectional axial loads.

Features: Suitable for applications that need to bear bidirectional axial forces, such as some special types of crushers.

Structure: Add lubricant to the bearing material or adopt a special lubrication structure.

Features: It has self-lubricating properties, reduces maintenance requirements, and is suitable for crushers that require long-term operation and inconvenient maintenance.

Structure: It consists of needle rollers and bearing races, and the needle rollers are closely arranged.

Features: It is suitable for applications with light to medium axial loads, with a compact structure and high load-bearing capacity.

Different types of thrust bearings are widely used in various types of crushers according to their characteristics and designs to meet different load and working conditions and ensure stable operation and long life of the equipment.