Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

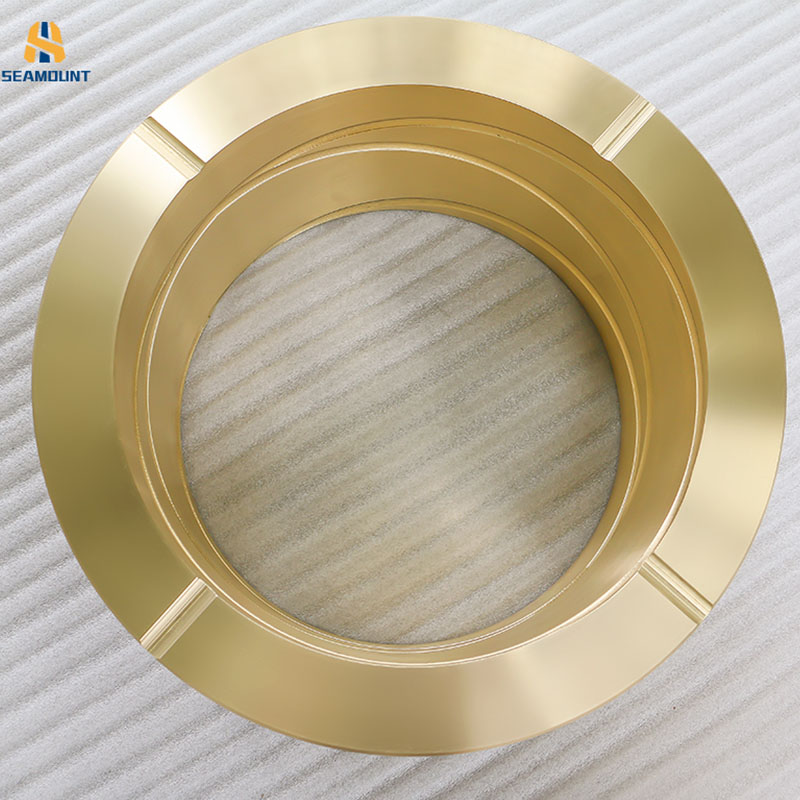

Cell phone +86 17630258963 Flange copper sleeve has some shortcomings in practical application, which may affect its performance and service life. In view of these problems, the corresponding solutions

can be taken to improve the performance and reliability of flange copper sleeve. The details are as follows:

Disadvantages of Flange copper sleeve

Flange copper sleeve disadvantage 1: high requirements for the working environment: flange copper sleeve in water or corrosive environment does not perform well, which will shorten

its service life.

Flange copper sleeve disadvantage 2: relatively low hardness: although the flange copper sleeve has good wear resistance, but compared to other metal materials, its hardness is still low,

which may lead to deformation or damage under high pressure or high load conditions.

Flange copper sleeve disadvantage 3: vulnerable to mechanical damage: because the copper material is relatively soft, the flange copper sleeve is vulnerable to bumps or scratches during

transportation and installation, affecting the sealing performance.

Flange copper sleeve disadvantage 4: limited heat resistance: although the copper material itself has a certain heat resistance, but at extremely high temperatures, the performance of the

flange copper sleeve may decline, and even deformation or burn.

Solution

Solution 1Use anti-corrosion coating: corrosion problems caused by the working environment can be solved by applying anti-corrosion coating (such as epoxy resin or polyurethane coating) on the

surface of the flange copper sleeve. This not only enhances its corrosion resistance, but also reduces the erosion of the external environment.

Solution 2Alloying treatment: alloying treatment by adding other metal elements (such as zinc, aluminum, etc.) can improve the hardness and strength of the copper sleeve of the flange, so as to

improve its reliability in high pressure environments.

Solution 3 To the shortcomings of the flange copper sleeve: Enhanced protective measures: During transportation and installation, increase protective measures (such as the use of cushioning

materials) to reduce mechanical damage. At the same time, operators are trained to ensure that care is taken during installation to avoid unnecessary collisions and scratches.

Solution 4 Improvement of the cooling system: For high temperature application scenarios, the working temperature of the flange copper sleeve can be reduced by improving the cooling system to

ensure that it operates within a safe range. For example, add heat sinks or cooling jackets to take away excess heat.

In summary, while flange copper bushing performs well in some applications, it may have limitations in highly corrosive environments, high hardness requirements, and high

temperature conditions. By adopting anti-corrosion coating, alloying treatment, enhanced protective measures and improved cooling system, these problems can be effectively solved to improve the overall performance and reliability of flanged copper sleeves.