Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 Different casting processes require the use of different types of molds, mainly including sand casting, centrifugal casting, gravity casting and continuous casting.

Scope of application: suitable for complex shape, large size or small batch production of copper castings.

Mold materials: sand molds are usually made of quartz sand, resin sand or water glass sand, with good high temperature resistance.

Advantages: lower cost, flexible manufacturing, suitable for complex structure of copper castings.

Disadvantages: the mold can not be reused, the surface finish of the casting is poor, and requires subsequent processing.

Scope of application: suitable for gravity casting, centrifugal casting and other high-precision casting process, suitable for mass production and more accurate size of copper castings.

Mold material: metal molds are usually made of cast iron or cast steel and other high-temperature-resistant metal materials, with a long service life.

Advantages: mold durability, can be reused many times, casting surface finish and high dimensional accuracy.

Disadvantages: the initial mold manufacturing cost is higher, suitable for mass production.

Scope of application: for the production of pipes, bars or other continuous casting of copper castings.

Mold materials: generally use metal materials with good wear resistance, such as steel or copper alloy, for maintaining structural stability at high temperatures.

Advantages: high production efficiency, suitable for mass production, good densification of castings, uniform internal structure.

Disadvantages: larger investment in equipment, suitable for standardized copper castings.

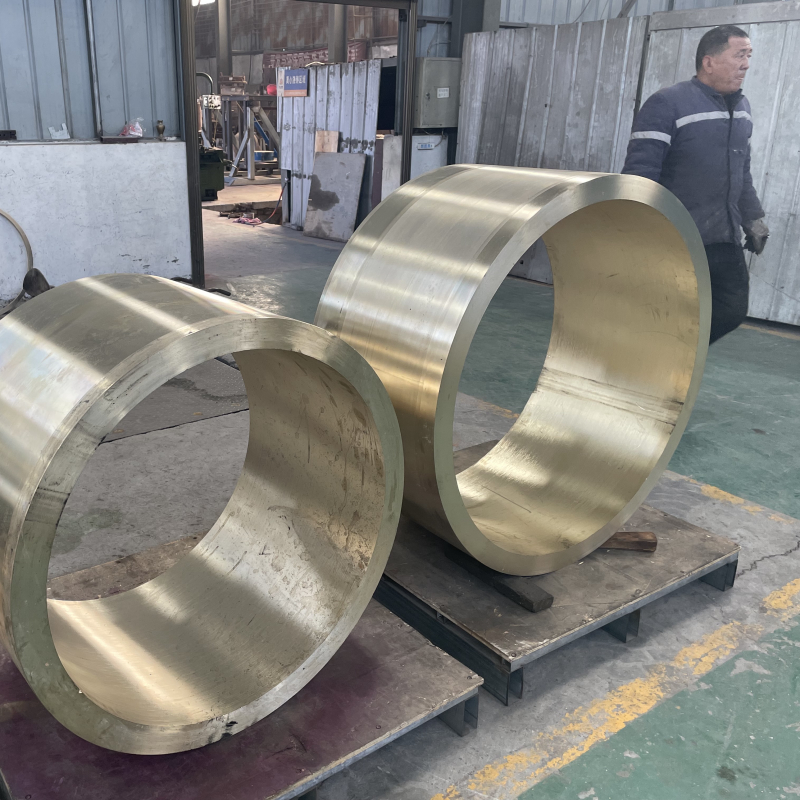

Scope of application: suitable for round, ring or tube-shaped copper castings, such as copper sets, copper rings, etc..

Mould material: usually steel molds, can withstand the centrifugal force generated by high-speed rotation and the impact of high-temperature copper liquid.

Advantages: high density of copper castings, reusable molds, suitable for the production of large quantities of tubular or hollow copper castings.

Disadvantages: only suitable for symmetrical shape copper castings, equipment investment is higher.