Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 Oiled bearings and graphite bronze bushings differ in several ways:

Material: mainly made of metal powder (usually copper powder, iron powder, etc.) after pressing and sintering. Contain a certain proportion of internal pores, these pores are stored in the lubricating oil.

Lubrication mode: rely on the internal pores of the stored lubricant in the working process gradually exuded to the friction surface, the formation of lubrication film.

With the operation of the bearing and the temperature rises, the lubricant oozing speed will be accelerated to ensure continuous lubrication effect.

Performance characteristics: self-lubricating performance is better, in the start-up and low-speed operation can also provide some lubrication. Relatively low cost, manufacturing process is relatively simple. Vibration absorption is good, can reduce the vibration and noise of the equipment operation. Load-bearing capacity is general, suitable for low and medium load occasions.

Application areas: commonly used in small motors, household appliances, office equipment and other fields. It is more suitable for the occasions with low speed and small load.

Maintenance: generally do not need to add lubricant frequently, but after a long time of use, if the lubricant consumption is too much, it may need to replenish the lubricant.

Requirements for the working environment are relatively low, but prolonged use in extreme environments such as high temperature and high humidity should be avoided so as not to affect the performance of the lubricant.

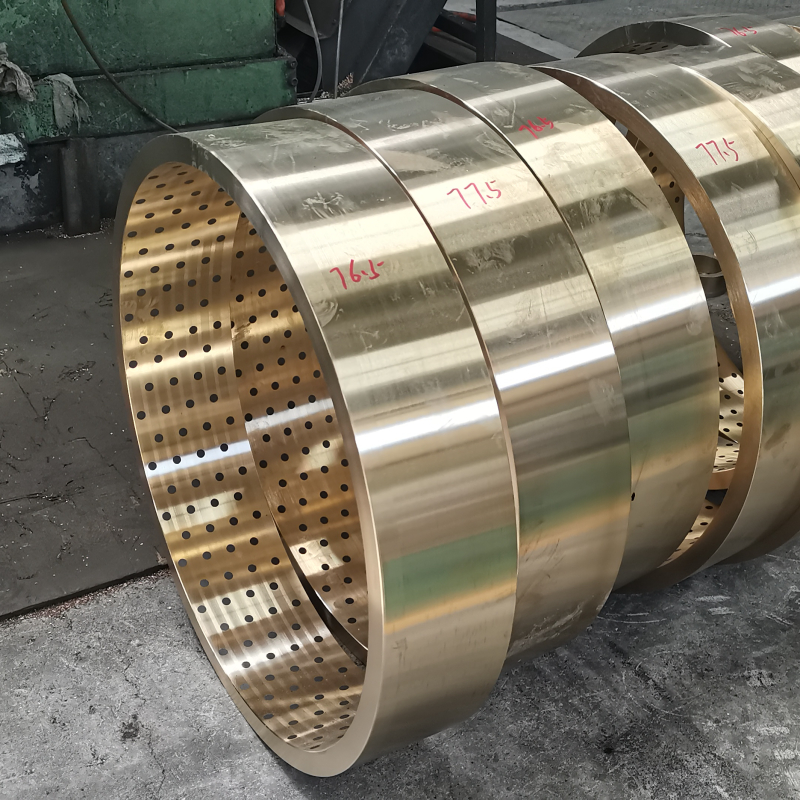

Material: Consists of a copper matrix with graphite particles embedded in it. Copper provides strength and thermal conductivity, while graphite gives self-lubricating properties.

Lubrication mode: mainly rely on graphite particles in the friction surface to form a lubricating film. Graphite has good self-lubricating properties and can be lubricated to a certain extent without the addition of external lubricants. However, in some special cases, it can also be used with external lubrication to improve performance.

Performance characteristics: high strength and load-bearing capacity, can withstand greater pressure and impact. Good abrasion resistance and thermal conductivity, help dissipate heat and prevent overheating. Stable self-lubricating performance, in high temperature, high load and other harsh environments can still maintain good performance.

Application areas: widely used in various mechanical equipment, such as crushers, conveyors, mixers, pumps and so on. Especially in mining, metallurgy, chemical industry and other harsh working environment, graphite copper sleeve performance advantages are more obvious.

Maintenance: Regularly check the wear situation, such as serious wear should be replaced in time. Keep clean to prevent impurities from entering the mating surface of copper sleeve and shaft, which will affect the lubrication effect. In some special occasions, it may be necessary to adjust the lubrication method and maintenance cycle according to the working conditions.