Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 Copper gaskets made of different materials have the following differences in sealing performance:

Sealing performance characteristics: pure copper gasket has good ductility and flexibility, can better adapt to the sealing surface of the tiny unevenness, so as to form a good seal. Pure copper has good thermal conductivity, in some high-temperature environment, can quickly conduct the heat out, reduce the impact of local overheating on the sealing performance. However, pure copper is relatively soft, under high pressure environment, excessive deformation may occur, affecting the stability of the seal.

Applicable scenarios: Suitable for low and medium pressure, moderate temperature sealing occasions, such as general plumbing pipe connection, part of the sealing of small machinery and equipment.

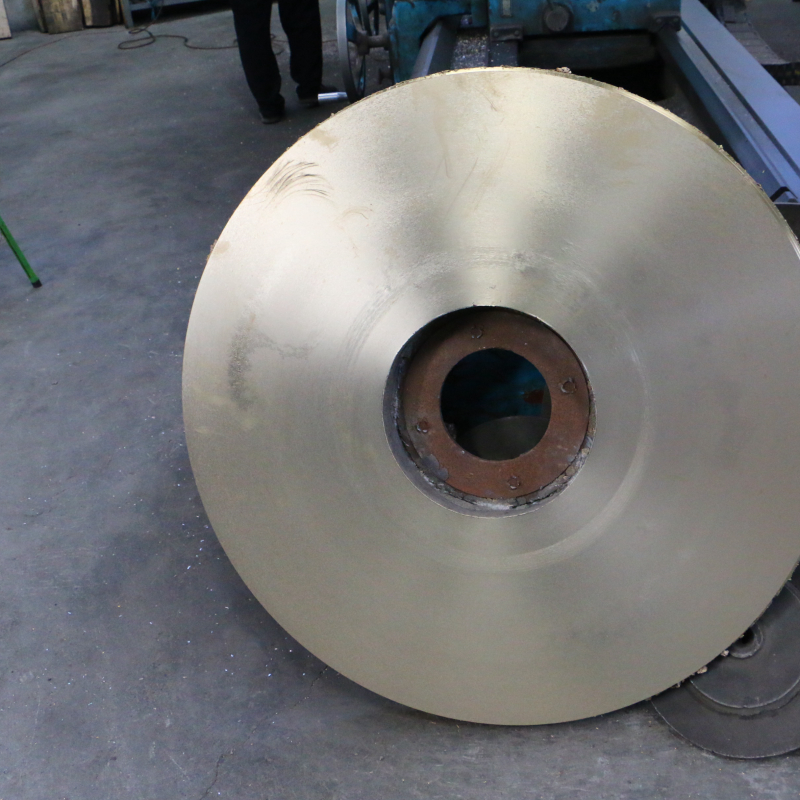

Sealing performance characteristics: brass is a copper-zinc alloy, higher than the hardness of pure copper, so to a certain extent can withstand higher pressure and not easy to excessive deformation. Brass gasket sealing performance is more stable, is not easy to be affected by the temperature change is too large. But brass in some corrosive environment, such as contact with strong acid, strong alkali, etc., easy to corrode, thus reducing the sealing performance.

Applicable scene: commonly used in general industrial equipment sealing, such as ordinary valves, pumps, etc., the sealing requirements are not particularly high occasions.

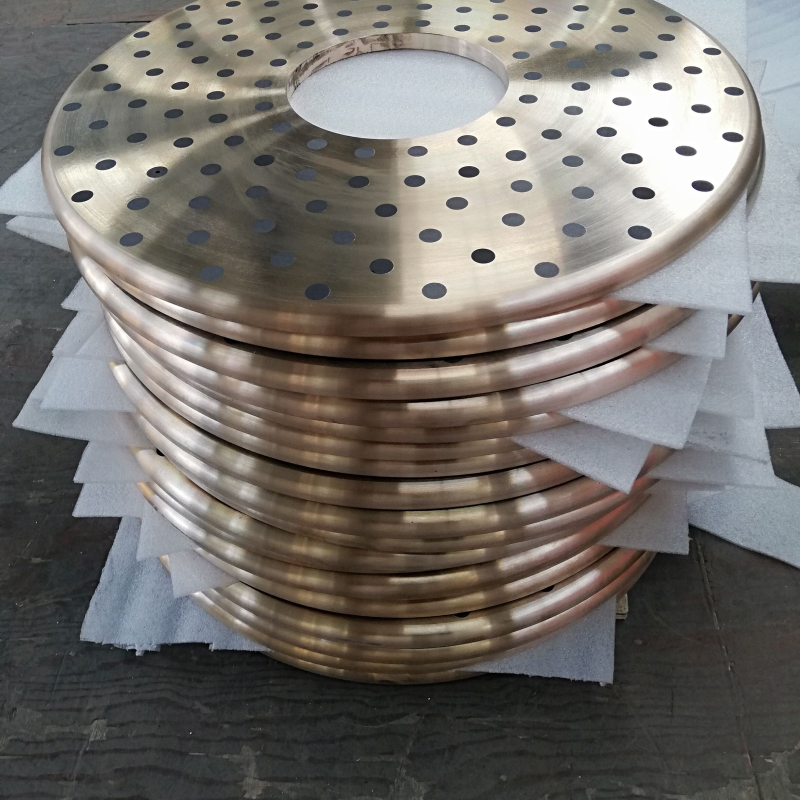

Sealing performance characteristics: tin bronze has high strength and corrosion resistance, can maintain good sealing performance in a relatively harsh environment. It has good resistance to some corrosive media, such as acid, alkali, salt solution. At the same time, the elasticity and toughness of the tin bronze gasket is also better, and can maintain the reliability of the seal within a certain range of pressure changes.

Applicable scene: suitable for chemical, petroleum, pharmaceutical and other industries, contact with corrosive media or require high sealing performance of the equipment.