Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 Copper gasket with different structural properties have the following differences in sealing performance:

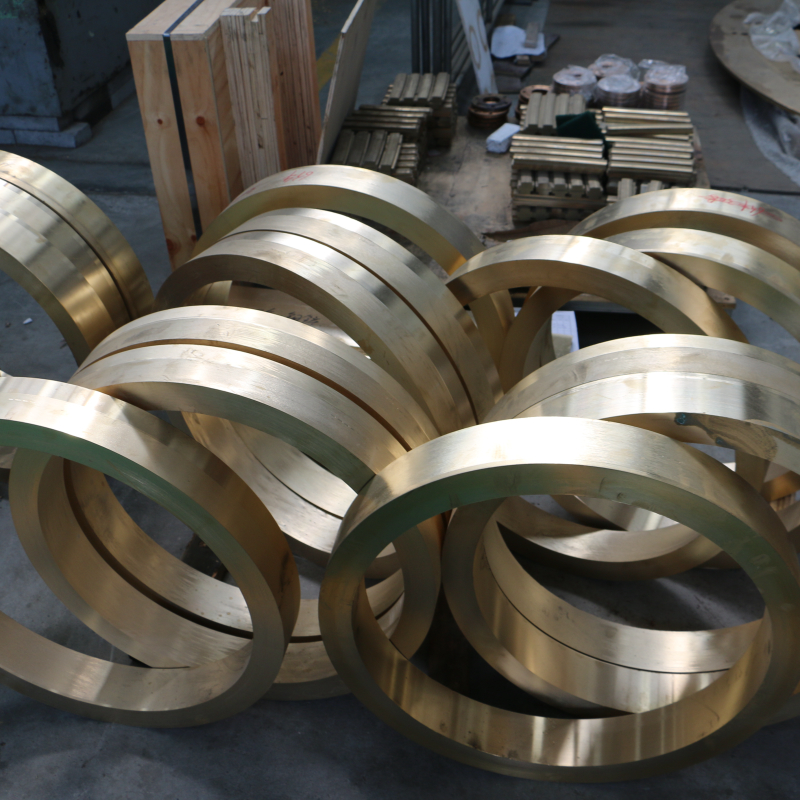

Sealing performance characteristics: flat gasket is the most common type of copper gasket with simple structure. It is mainly through the gasket and the sealing surface between the compression deformation to realize the seal. The sealing performance of flat gasket depends on its material, thickness and compression force during installation. If the compression force is insufficient, leakage will occur easily; if the compression force is too large, it may lead to gasket damage or excessive deformation.

Applicable Scenario: Widely used in various general sealing occasions, such as pipe connection, flange sealing and so on.

Sealing performance characteristics: wave gasket has a certain elastic deformation ability, can produce elastic deformation under pressure, so as to better adapt to the changes in the sealing surface and improve the sealing performance. It can compensate for the unevenness of the sealing surface and the dimensional changes caused by thermal expansion and contraction, reducing the risk of leakage. In addition, the waveform gasket can also play a certain role in shock absorption.

Applicable scenarios: suitable for pressure fluctuations, sealing surface is not too flat or there is a certain vibration occasions, such as engines, compressors and other equipment sealing.

Sealing performance characteristics: toothed gaskets have a tooth-like structure on the sealing surface, these teeth can be embedded in the sealing surface to increase the reliability of the seal. Toothed gaskets require a large compression force during installation so that the teeth can be firmly embedded in the sealing surface to form a good seal. It has better sealing performance and can withstand higher pressure and temperature.

Applicable Scenario: Commonly used in high-pressure, high-temperature sealing occasions, such as high-pressure containers in the petrochemical industry, pipeline flanges and so on.