Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

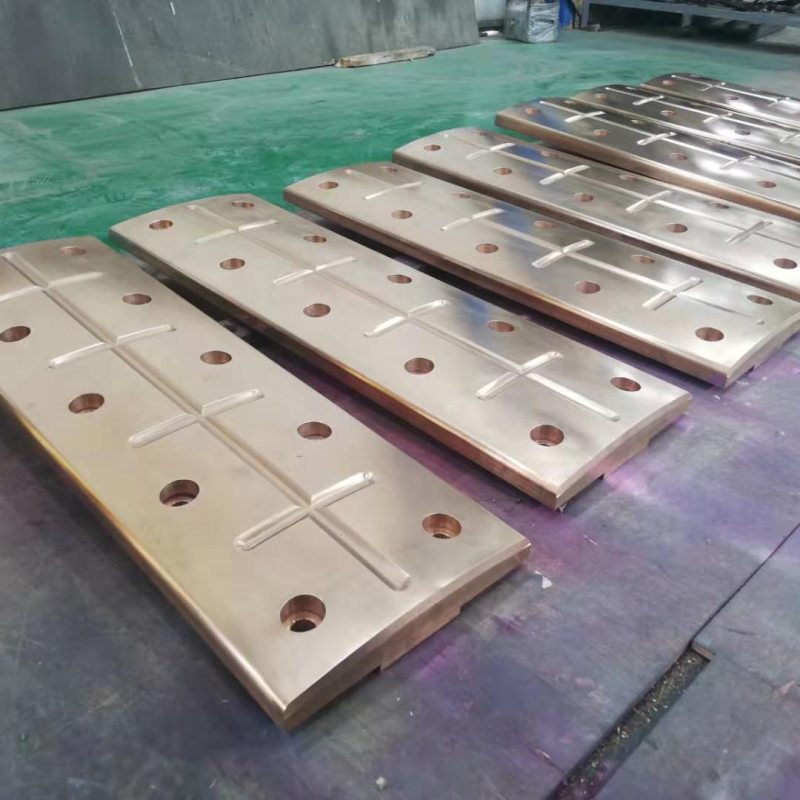

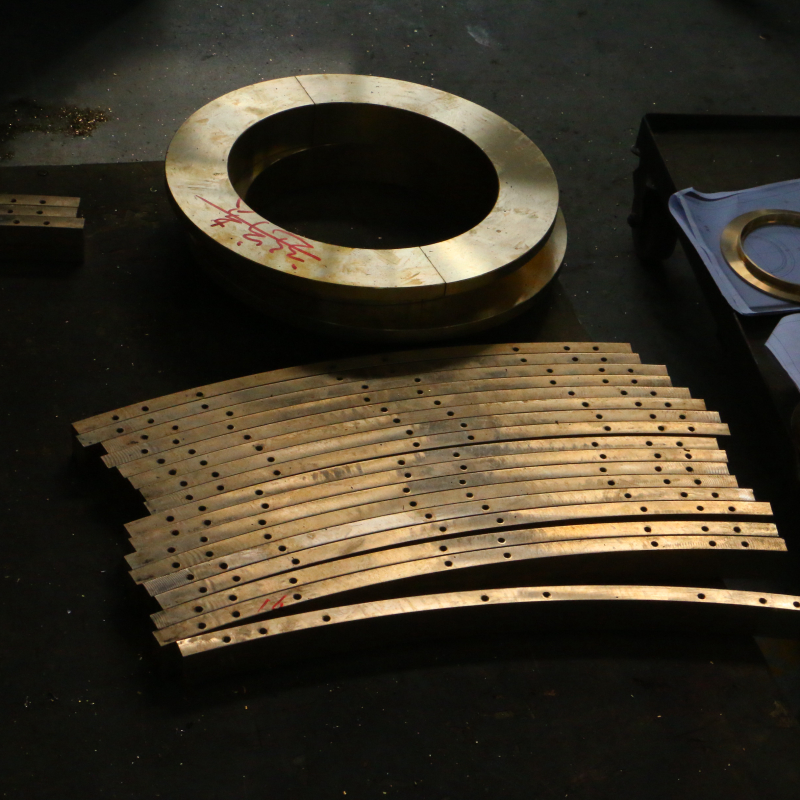

Cell phone +86 17630258963 Different copper slide plate processing process has the following effects on its hardness:

Ordinary casting: relatively low hardness. In the ordinary casting process, the copper liquid cooling rate is slower, the grain is more coarse, the organization is not dense enough, which will lead to the hardness is not high. There may be a certain compositional segregation, further affecting the uniformity of hardness.

Precision casting: hardness is improved. Precision casting can obtain finer castings, relatively fast cooling speed, grain refinement, organization uniformity is better, so that the hardness is higher than ordinary casting.

Free forging: can significantly improve the hardness. Through repeated upsetting, pulling long and other operations, so that the grain of the metal is refined, dislocation density increases, thus improving the hardness. The work hardening effect in the forging process is obvious, which can make the hardness of the copper slide plate increase greatly.

Die forging: uniform and higher hardness. Within the confines of the die, the metal is deformed more uniformly and the organization is denser, so the hardness is more uniform and usually higher than in free forging. Die forging can accurately control the processing parameters to ensure the stability of product quality, thus ensuring the consistency of hardness.

Cold rolling: significantly increase the hardness. Cold rolling process, copper slide by strong plastic deformation, grain is elongated, broken, dislocation density increases dramatically, resulting in significant work hardening phenomenon, hardness increased significantly. Hardness can be adjusted by controlling the amount of cold rolling deformation, the larger the deformation, the higher the hardness.

Cold Drawing: The hardness increases significantly. Cold drawing makes the copper material plastic deformation along the axial direction, which also leads to grain refinement and dislocation density increase, thus improving the hardness. Cold drawn copper skateboards have higher dimensional accuracy and surface quality, and the hardness is correspondingly higher.

Annealing: reduce hardness. Annealing is a copper slide heated to a certain temperature and then slowly cooled, the purpose is to eliminate internal stress, improve the organization, reduce hardness, improve toughness. Different annealing temperature and time will have different degrees of impact on the hardness.

Quenching: significantly improve the hardness. Quenching is to heat the copper slide plate to a high temperature and then rapidly cooled, so that the organization of copper transformation, the formation of higher hardness martensite or other reinforced phases, thereby significantly increasing the hardness. The quenching process requires a high cooling rate, otherwise the hardness enhancement effect will be affected.

Tempering: Adjustment of hardness. Tempering is a heating treatment carried out after quenching to reduce the brittleness after quenching and to adjust the hardness at the same time. The level of tempering temperature will affect the change of hardness, generally speaking, the higher the tempering temperature, the lower the hardness.