Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 Advantages:

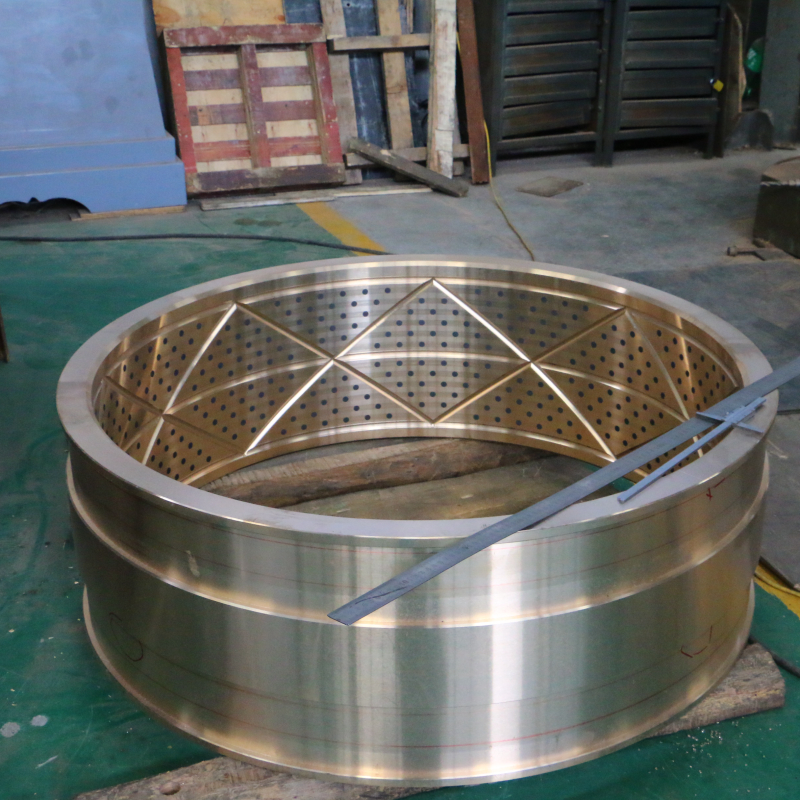

Good self-lubrication: graphite copper bushing in the work, graphite particles will form a stable solid lubrication diaphragm on the friction surface, without the need to add additional lubricant, can realize oil-free or oil lubrication, reduce the workload and cost of equipment maintenance, suitable for some difficult to refuel or do not allow oil contamination of the working environment.

High bearing capacity: with copper alloy as the substrate, graphite copper bushing have high mechanical strength and bearing capacity, able to withstand large radial and axial forces, commonly used in heavy-duty mechanical components.

Strong abrasion resistance: graphite itself has good abrasion resistance, combined with the copper alloy matrix, further improve the wear resistance of the material, can be in the high load, high speed conditions of long-term stable operation, reduce wear and tear of components, extend the service life of the equipment.

Adapt to harsh environments: graphite copper bushings have good resistance to high temperature and corrosion, can work in high temperature, high humidity, vacuum and other harsh conditions and some corrosive media environment.

Low friction coefficient: effectively reduce the friction coefficient between the bearing and the shaft, reduce energy loss, improve mechanical efficiency, reduce the operating energy consumption of the equipment.

Disadvantages:

Insufficient precision and rigidity: the manufacturing process of graphite bronze bushings leads to relatively poor precision and rigidity, difficult to achieve high standards, not applicable to the strict requirements for precision and rigidity of the occasions, such as high-precision machine tool spindles, precision instrumentation transmission components.

High-speed performance is not good: in high-speed operation, graphite lubrication performance is limited, and the structure and material properties make it easy to produce a large centrifugal force, affecting the stability and service life of the bearing, generally not suitable for high-speed high load working environment.

Limited pressure resistance: the graphite material in graphite bronze bushings has a certain degree of brittleness, pressure resistance is relatively weak compared to ordinary bronze bushings, easy to rupture and damage when subjected to excessive pressure, resulting in component failure, so there is a risk of using in high-pressure working conditions.

Limited service life: although good wear resistance under normal working conditions, but in extreme working conditions or long-term high load operation, the wear speed may accelerate, shorten the service life, compared with some special alloys or advanced surface treatment technology of copper bushings do not occupy an advantage.

Higher installation requirements: graphite copper bushings need to be installed in strict accordance with the operating procedures and technical requirements, otherwise it is easy to damage or affect the normal lubrication and performance, increasing the cost and difficulty of installation.

sgraphite in the use of the process is prone to generate dust, may cause pollution to the working environment, but also to the operator's health potential hazards.