Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

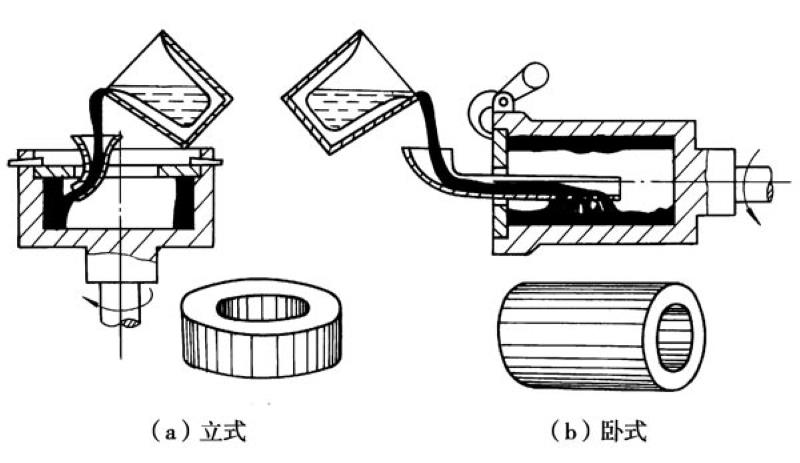

Cell phone +86 17630258963 Centrifugal casting is a casting method in which liquid metal is poured into a rotating mold, filling the mold cavity and solidifying under the action of centrifugal force to obtain castings.

In centrifugal casting, liquid metal can effectively overcome the influence of gravity under the action of centrifugal force, and is strongly thrown towards the inner wall of the mold, allowing more opportunities for gases, inclusions, etc. in the metal liquid to gather and be discharged to the central part. At the same time, it also promotes better shrinkage of the metal liquid during the solidification process, making the internal structure of the casting denser and improving its mechanical properties. For example, indicators such as strength and hardness can often reach a high level, effectively reducing the probability of common casting defects such as shrinkage and porosity. The dimensional accuracy is high. Due to centrifugal force, the liquid metal can be evenly distributed on the inner wall of the mold. After cooling and solidification, the uniformity of the wall thickness of the casting can be well guaranteed, especially for some rotary castings, whose external dimensional deviations are relatively small, making it easier to meet strict dimensional tolerance requirements. The subsequent machining allowance can be appropriately reduced, reducing machining costs and material losses. High material utilization and low subsequent processing costs.

In summary, centrifugal casting has a wide and important application in the casting industry, especially in the production of rotary castings, due to its advantages in casting quality, process adaptability, and cost control.