Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

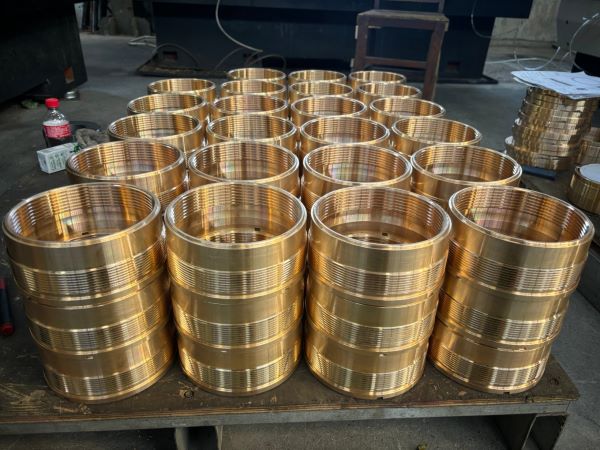

Cell phone +86 17630258963 Aluminum bronze is a copper based alloy with aluminum as the main alloying element, commonly divided into simple aluminum bronze and complex aluminum bronze.

A simple binary aluminum bronze with an aluminum content of around 5% -11% has good strength, hardness, and certain wear resistance. Its corrosion resistance also performs well in some conventional environments, and its processing performance is relatively moderate. It is commonly used to manufacture ordinary mechanical parts with certain requirements for mechanical properties and corrosion resistance, such as small gears, shaft sleeves, etc. Complex aluminum bronze comes in various forms such as aluminum iron bronze, aluminum manganese bronze, aluminum silicon bronze, etc., which can significantly improve the strength, hardness, and wear resistance of alloys. This alloy is suitable for fields such as marine engineering, chemical industry, mechanical engineering, aerospace, etc. It is used to manufacture components in high load and high wear environments such as seawater treatment equipment, ship parts, chemical equipment and pipelines, gears, bearings, valves, and pumps.

Therefore, products produced using aluminum bronze alloy have different advantages and disadvantages, and we need to choose based on the usage environment, requirements, and strength of the product.