Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

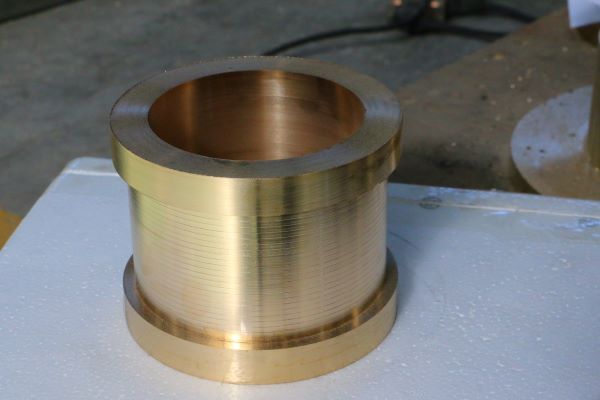

Cell phone +86 17630258963 For the use of bearings, regular maintenance and upkeep are essential. When it comes to the dimensional accuracy, rotational accuracy, internal clearance, mating surfaces, raceway surfaces, rolling surfaces, retainers, and sealing rings of bearings, any abnormal phenomena need to be repaired or even replaced.

Although the volume of bearing products is small, they have very powerful functions, which can help the equipment to achieve efficient operation and improve the operating efficiency of the equipment. To determine whether a bearing can be reused, it is necessary to consider the degree of bearing damage, machine performance, importance, operating conditions, inspection cycles, and other factors before making a decision. If damage or abnormal conditions are found in the bearings during the inspection, the cause should be identified in the section on damage and countermeasures should be formulated. In addition, according to the inspection results, if there are any of the following defects, the bearing cannot be used anymore and needs to be replaced with a new one.

1. Any one of the inner and outer rings, rolling elements, and retaining frames has cracks or fragments.

2. Either the inner or outer circle or the rolling element is peeled off.

3. The rolling surface, blocking edge, and rolling element have significant jamming damage.

4. The retainer is severely worn or the rivets are loose.

5. Rust and scratches on the raceway surface and rolling elements.

6. There are significant indentations and marks on the rolling surface and rolling elements.

7. There is creep on the inner diameter surface of the inner ring or the outer diameter of the outer ring.

8. Overheating causes severe discoloration.

9. The sealing ring and dust cover of the grease sealed bearing are severely damaged.

In addition, the general operating time of bearings is 2-3 years. If the time is up, important equipment should be considered for replacement.