Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

Cell phone +86 17630258963 In industrial production, copper sleeves play an important role, and mechanical testing of them is a key link to ensure quality, with multiple testing methods available.

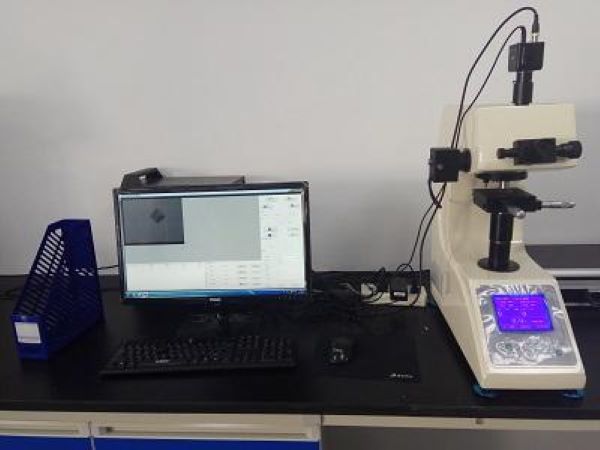

Hardness testing is a commonly used method. For example, the Rockwell hardness test measures the ability of copper sleeves to resist deformation through different load quantities and indenter configurations, which is particularly suitable for testing copper sleeves with thickness requirements. There is also Brinell hardness testing, but it is more suitable for testing thicker large bar and plate copper sleeves. The Vickers hardness test can be flexibly applied to copper sleeves of different weights. Tensile testing is also indispensable. By axially stretching the standard specimen under specified conditions, important indicators such as yield strength and tensile strength can be obtained, which can clearly understand the strength and plasticity of the copper sleeve material and assist in selecting suitable materials for production. The bending test can evaluate the flexibility and bending resistance of copper sleeves, and check for any defects inside. The impact test reflects the performance of the copper sleeve under dynamic loads by impacting the specimen with a pendulum. In addition, fatigue testing can simulate cyclic loads, predict the number of times copper sleeves can withstand long-term use, and ensure their service life.

These mechanical testing methods are like multi-faceted mirrors, allowing the quality condition of the copper sleeve to be clearly presented.