Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Mazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

Service Hotline +86 17630258963

Service Hotline +86 17630258963  Cell phone +86 17630258963

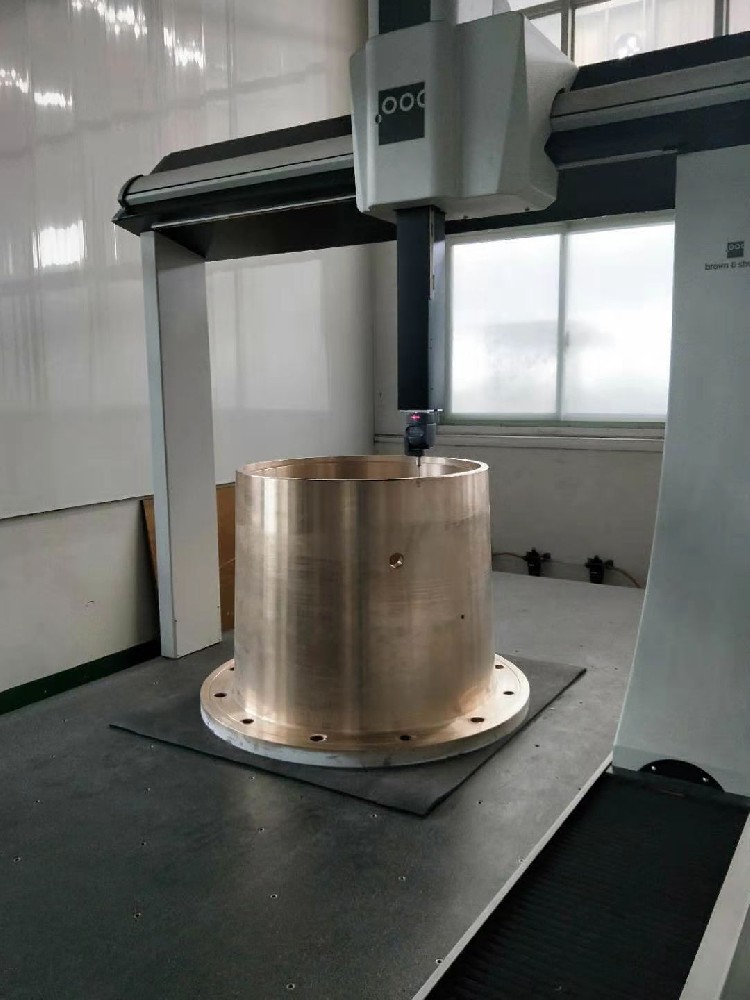

Cell phone +86 17630258963 Coordinate Measuring Machine (CMM) Inspection Methods and Tools

Trigger probe inspection: Trigger probe triggers the measurement when it touches the surface of copper fittings, commonly used for simpler geometries and large sizes of copper fittings.

Scanning probe inspection: Scanning probes continuously collect data by contacting the surface of copper fittings, suitable for complex curved surfaces and high precision measurements.

Laser Scanning: Laser scanning probes use a laser to non-contact measure the surface of the part and are suitable for measuring soft or easily deformed copper materials.

Optical Image Measurement: Non-contact measurement using a camera and optical system, commonly used for small, delicate and irregularly shaped copper fittings.

Probe systems: Including trigger probes, scanning probes and laser scanning probes, the selection of the appropriate probe is based on the characteristics of the copper fittings and accuracy requirements.

Measurement software: Software tools for data acquisition, analysis, modelling and report generation, e.g. PC-DMIS, Calypso, etc.

Fixing fixtures: Used to fix the copper fittings to the CMM platform to ensure stability during the measurement process.

Environmental control: CMMs usually need to operate in a controlled environment such as temperature and humidity to minimise measurement errors.